Water scarcity, water costs and awareness of water management issues all contribute to the increasing use of water re-circulation systems. However, recirculating water presents a new set of challenges in preventing the spread of bacterial, fungal and viral spores. Without the right water treatment, infections can spread to entire productions.

Infections can enter horticultural productions with new soil, new seeds or from rainwater used for irrigation. These sources of infection can introduce bacteria or different types of fungi such as fusarium to your production. Fusarium is particularly difficult to eliminate and can be pernicious for your crop.

The spread of infection to healthy plants is a considerable challenge for growers – especially when water is recirculated in horticultural irrigation and fertilizing set-ups.

If an infection has spread, the irrigation system needs chemical treatment, and the loss can be substantial. In a production potentially worth millions, significant losses can be extremely critical.

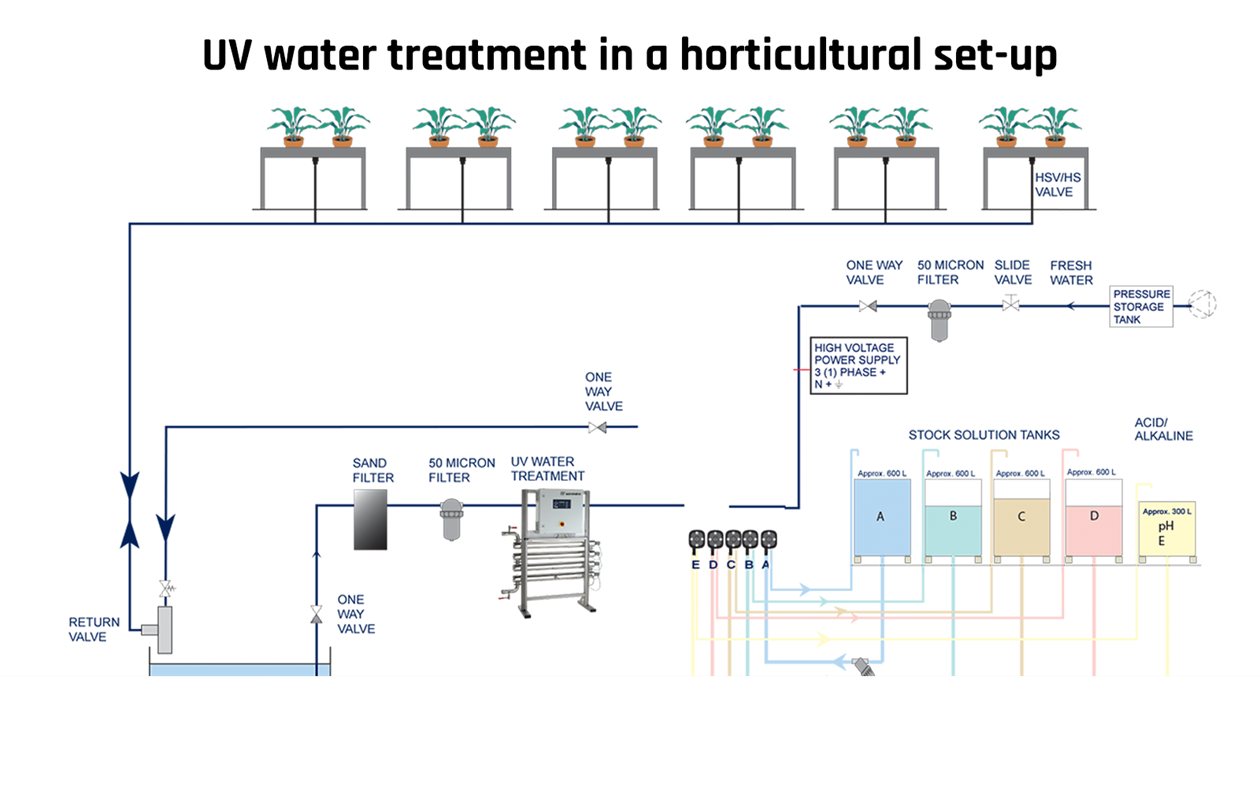

In an irrigation set-up, approximately 80 percent of water is reused, both to save water resources and money, and to minimize fertilizer consumption. When water is reused, it is initially filtered through a sand filter, which removes particles, leaves, and other organic material. Then, the water is filtered through a disc filter, which removes possible sand. In several greenhouses, this completes the water treatment and the filtered water is then reused for irrigation. With this setup, potential infections are not eliminated, and if bacterial, fungal or viral spores have entered the water, the infection can spread to healthy plants throughout the production.

UV water treatment removes all bacteria and fungi, ensuring that any potential infection is eliminated. By exposing water to UV light in a filter consisting of several light bars, the water is completely disinfected. The number of light bars needed in the system is calculated on the basis of water transparency and flow. If the water transparency is low, the UV lights will struggle to reach and thereby disinfect all of the water – therefore, the lower the transparency, the more UV light bars are needed. UV water treatment is the most efficient way to ensure that no infection will spread to the rest of your produce when recirculating water.

Tips for disease management

Besides implementing a UV filter in your irrigation and fertilizing set-up, you can take several steps to avoid disease in your production:

- Inspect seedlings and incoming cuttings by looking for localized symptoms such as leaf spots, shoot blights, root rot symptoms, and root lesions.

- Ensure an optimal watering strategy.

- Remove all diseased plants and put them in sealed plastic bags.

- Inspect plants regularly – at least 5% of all plants in the crop.

- Infection risk is highest during fall – be extra careful at that time of year.

- Secure the entry to the greenhouse, so bacteria are not introduced by people entering.

- Do not pile pruned material near the greenhouse.

- Establish good temperature and humidity management in your greenhouse with a climate computer.

An inexpensive insurance for your greenhouse watering system

There are several entry points for diseases in your production, and therefore you will rarely be able to pinpoint exactly when or how an infection entered. UV water treatment is your insurance against spread if an infection should occur.

The UV water treatment solution from Senmatic is environmentally friendly, easy to implement, and can easily be added to a new or existing greenhouse watering system.