WIND ENERGY

OPERATING IN EXTREME CONDITIONS

Wind installations are complex setups often operating under extreme conditions. This creates a need for reliable monitoring, precise troubleshooting and competent optimization to ensure efficiency.

To do so, the wind turbine industry needs business partners, who understand the need for high efficiency, maximum reliability, and minimum downtime in installations. With know-how from 20 years of experience in the wind industry, we work with leading players in the industry, designing and manufacturing reliable temperature and humidity sensors for demanding wind power applications.

For further information, you are welcome to contact one of us:

Mike Wang Zhang Jingfeng

National Sales Manager Sales Manager

Phone: +86 13910814128 Phone: +86 13585791751

Email: Send email Email: Send email

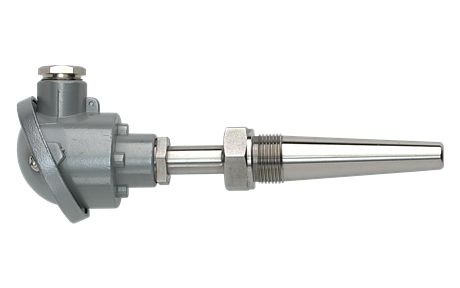

Reliable temperature and humidity sensors for the wind industry

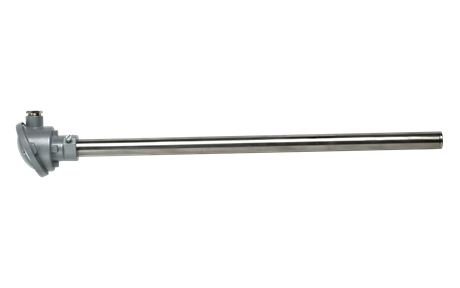

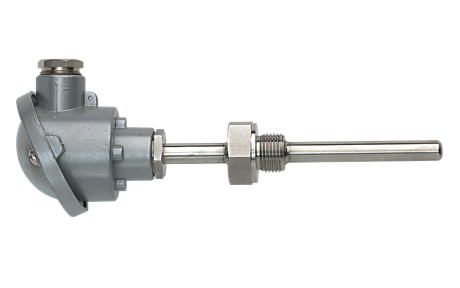

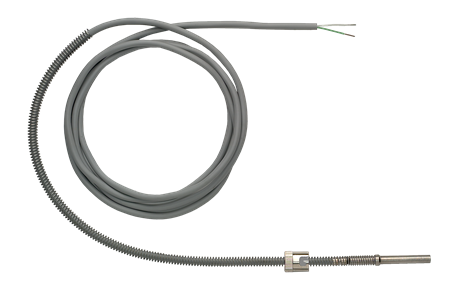

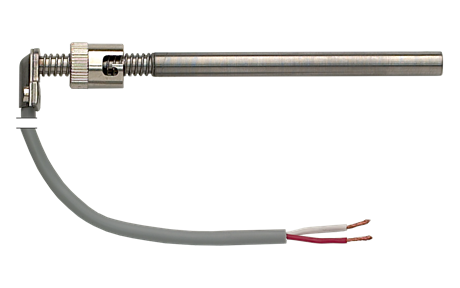

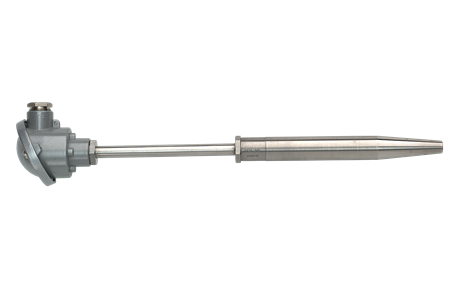

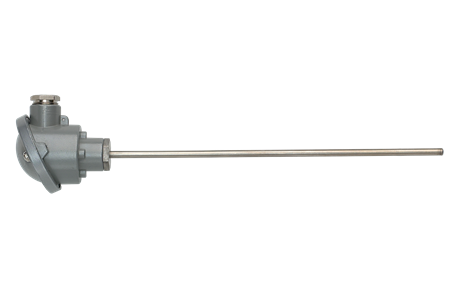

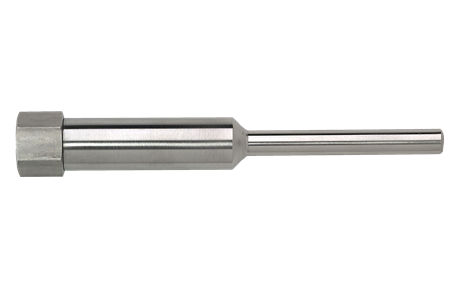

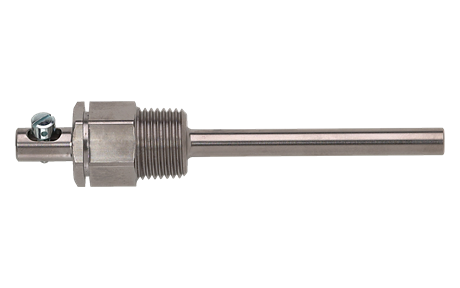

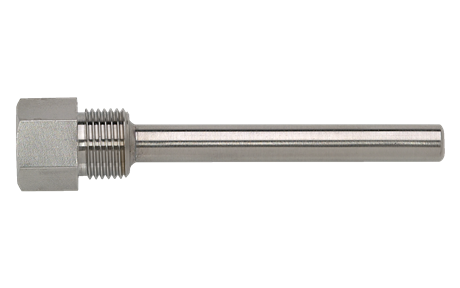

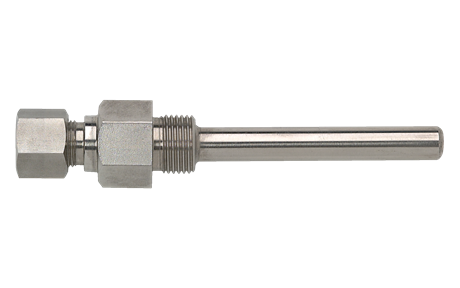

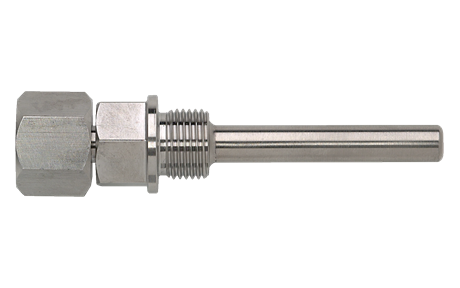

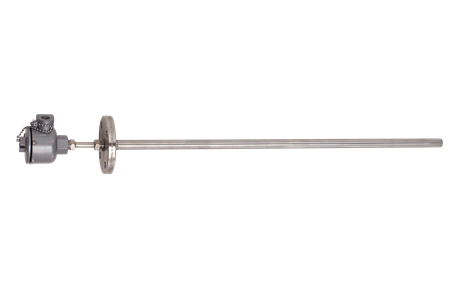

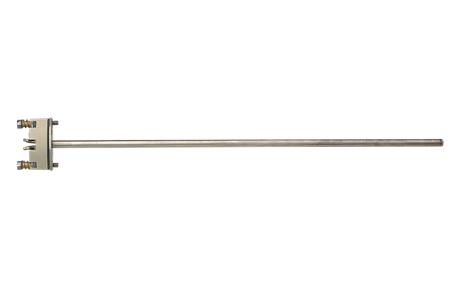

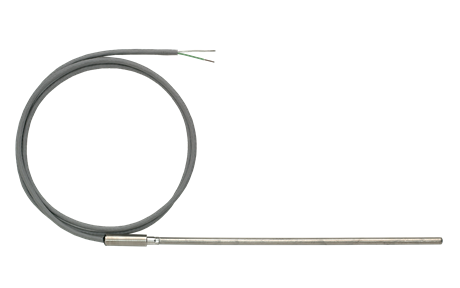

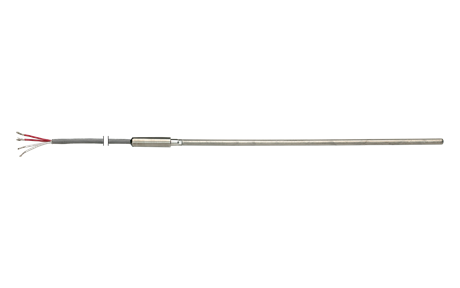

Our temperature and humidity sensors are designed to work under extreme operating conditions for both onshore and offshore wind turbines as well as turbines installed in remote sites. Our sensors for the wind power industry consist of:

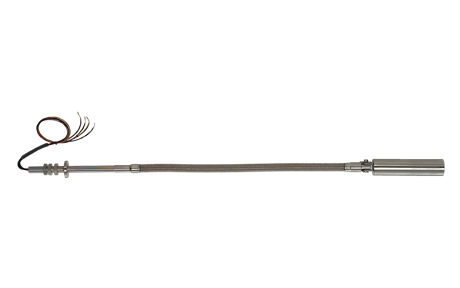

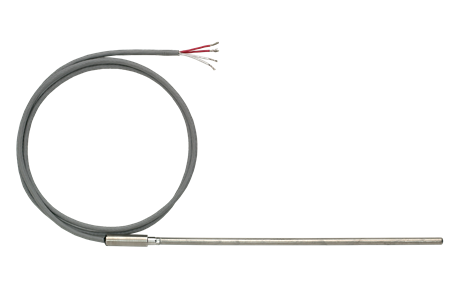

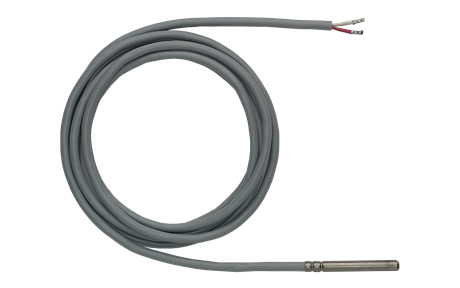

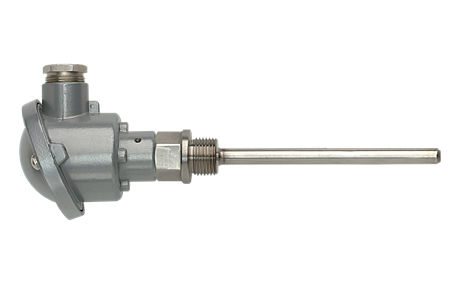

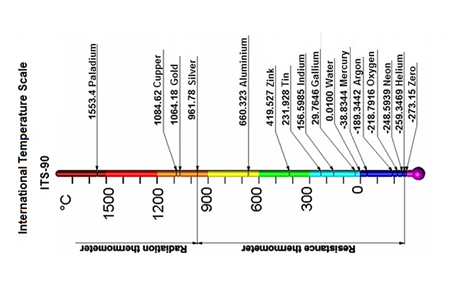

- Resistance temperature sensors (Pt-100 or Pt-1000) for monitoring outside temperature, control cabinets, transformers, generators, gearboxes, bearings, brakes, and hydraulics.

- Humidity sensors for monitoring of moisture in nacelle or tower.

Read about how to increase revenue by preventing humidity-related issues in wind turbines.

Meeting manufacturability and quality requirements

Producing reliable sensors demands that suppliers meet manufacturability and quality requirements, which is why APQP4Wind and Production Part Approval Process (PPAP) are essential parts of Senmatic’s operations in sensor production. The purpose of PPAP is to establish confidence in suppliers’ production processes, and to demonstrate that manufacturing is able to produce components that meet all requirements during the actual production run.

Core elements of PPAP at Senmatic is Design Failure Mode Effect Analysis (DFMEA) and Process Failure Mode Effect Analysis (PFMEA), where we ensure optimal sensor development and production.

Find the right sensor for your business

Transmitters

For any purpose